Different grades of hyaluronic acid are used quite differently due to differences in their properties and purification level. The article is about to provide an in-depth discussion on four important grades of hyaluronic acid raw materials for a better idea about their properties and uses.

| Four Grades of Hyaluronic Acid Raw Material Comparison | ||||

| Raw Material Category | Properties | Product Classification | Core Technology | Product Applications |

| Pharmaceutical Grade | Biocompatibility, viscoelasticity, lubricity | Pharmaceutical topical grade | Microbial fermentation technology | Eye drops, contact lens solutions, topical medications, oral preparations, etc. |

| Medical device grade | Wound healing topical preparations, cavity lubricants, drug carriers, ophthalmic viscosurgical devices, soft tissue fillers, anti-adhesion agents, membrane preparations, etc. | |||

| Injectable Grade | Biocompatibility, viscoelasticity, lubricity | Injectable grade | Microbial fermentation technology | Ophthalmic viscosurgical devices, soft tissue fillers, anti-adhesion agents, medications for knee arthritis, osteoarthritis, frozen shoulder improvement, etc. |

| Cosmetic Grade | Moisturizing, film-forming, bioactivity | Sodium hyaluronate raw material | Microbial fermentation technology, bio-enzymatic cutting technology, cross-linking technology | Sun protection, cleansing, moisturizing, repairing, antioxidant, anti-competitor skincare, haircare, makeup, cleansing and other products |

| Sodium hyaluronate derivatives | ||||

| Food Grade | Solubility | Sodium hyaluronate | Microbial fermentation technology | Gels, tablets, powders, oral liquids and other health foods or beverages, candies and other ordinary foods |

| Hyaluronic Acid Supplier: stanfordchem.com; hyaluronicacidsupplier.com | ||||

Medical Grade Hyaluronic Acid

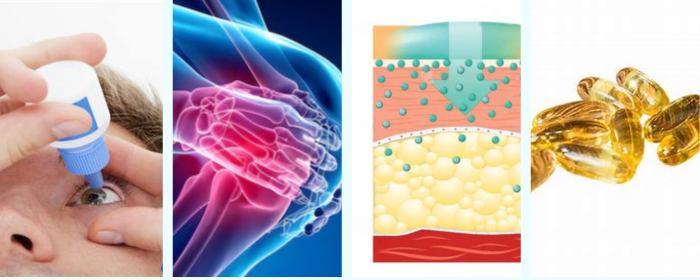

Medical grade hyaluronic acid has stringent purity and biocompatibility standards. Such raw material is usually produced by microbial fermentation technology to offer superior viscoelasticity and lubrication properties. In medicine, it is mainly divided into two broad categories: topical grade and medical device grade.

Topical grade applications are extremely common in typical medical products such as eye drops and contact lens solutions. On the other hand, medical device grade applications are more specialized, such as wound healing preparations, ophthalmic surgery, viscosurgical devices, and soft tissue fillers. All these products must comply with strict pharmacopoeia standards to ensure their safety and efficacy.

Injection Grade Hyaluronic Acid

Injection grade hyaluronic acid is similar in application to pharmaceutical grade, but with more stringent safety and stability standards. It is applied as a standard product within the medical aesthetic field, for example, facial fillers and lip enhancements, and also for conditions like osteoarthritis and frozen shoulder. These are often formulated to be specially cross-linked so that products remain longer within the body.

Cosmetic Grade Hyaluronic Acid

Cosmetic grade hyaluronic acid has become a star ingredient in skincare products due to its excellent moisturizing and film-forming properties. According to molecular weight and modification methods, it is further divided into basic sodium hyaluronate and various derivatives, such as acetylated hyaluronic acid, which can more effectively penetrate the skin and enhance moisturizing effects.

This type of raw material is widely used in products such as serums, masks, and lotions, and is often combined with other active ingredients like ceramides or vitamin C to improve overall skincare efficacy.

Food Grade Hyaluronic Acid

Food grade hyaluronic acid mainly focuses on solubility and safety and is suitable for various health foods and ordinary foods. In recent years, with the rise of the concept of ingestible beauty, hyaluronic acid has been added to products such as beverages and gummies, claiming to improve skin hydration and joint health.

Unlike pharmaceutical grade oral products, food grade hyaluronic acid is subject to relatively loose regulations but still needs to comply with food safety standards.

People Also Ask

What is the difference between medical grade and cosmetic grade hyaluronic acid?

Medical grade is of higher purity and safety standards and is used in medical applications, while cosmetic grade is more focused on function and end-user perception and is used for routine skin care.

Can injectable grade hyaluronic acid be used in skincare products?

Not recommended. Injectable grade products need to be in sterile conditions, while skincare products do not necessarily need to follow the same. Direct use can result in unnecessary wastage of money.

What is the difference between food grade hyaluronic acid and medical grade oral products?

Food grade is applied to normal foods and falls under loose regulations, while medical grade oral products need more rigorous drug standards, including drug purity and bioavailability testing.

Why do hyaluronic acids with different molecular weights have such different effects?

Molecular weight directly affects skin penetration rate and mechanism of action. High molecular weight (>1000kDa) mainly forms a moisturizing film on the skin surface; medium molecular weight (100-1000kDa) can penetrate the stratum corneum; low molecular weight (10-100kDa) can reach the dermis to stimulate collagen regeneration; and oligomeric HA (<10kDa) even has cell signaling regulation functions.

Does cross-linking technology reduce the safety of hyaluronic acid?

Modern cross-linking technologies (such as BDDE cross-linking) can control residual cross-linker content below 0.1ppm after strict purification treatment, fully complying with international safety standards. However, people with sensitive skin are still advised to do a patch test first.

What is the essential difference between microbial fermentation and animal extraction methods?

The fermentation method uses genetically engineered strains (such as Streptococcus) cultured in a sterile environment, with high product purity and no animal-derived risks; the traditional extraction method extracts from tissues such as rooster combs and is prone to residual heterologous proteins. It has now been phased out by the mainstream market.